Pfaudler’s Systems Expertise Applied to the Fragrance & Aroma Industry

17 February 2019

Pfaudler’s Systems Expertise Applied to the Fragrance & Aroma Industry

Raw material for fragrances and aromas can be used in various sectors, from cosmetics to perfume, from food and beverage to the nutraceutical industry. Pfaudler works closely with leaders in the food & aroma industries, further developing their knowledge of the chemical process; by designing complex and intricate systems widely used in these sectors.

In 2018 Pfaudler realized a significant project where custom-built, glass-lined reactors were supplied along with top-condensing, borosilicate glass equipment. The project was completed for an international leader specializing in the distillation and production of flavors and aromatic solutions. Thanks to the benefit of a global and broad portfolio, we have been able to ensure a complete and integrated system design, guaranteeing the functional operation of the unit.

A remarkable accomplishment of this project was the ability to combine the process knowledge & skills of our international teams, supply of our glass-lined reactors, along with a top-condensing borosilicate glass unit including a fractionation column. Pfaudler’s capabilities are not limited to the individual technologies themselves, but extend to a single-source solutions provider. In this project, Pfaudler assured the global support from the consulting services in the sales phase through the commissioning of the equipment, including engineering, design, manufacturing, installation services and complete assembly at site.

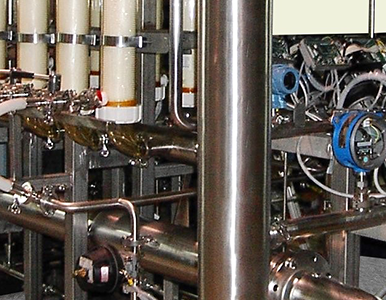

The glass-lined reactors type BE series with customized agitating systems, innovative sealing solutions and instrumentation provide the highest standard for efficiency, safety, reliability & economic operation.

The borosilicate glass-top condensing units consist of fractionation columns, condensers, phase separators and receivers manufactured by our branded product line NORMAG.

The high-performance structured packings in the columns are designed and supplied by our branded product line MONTZ. Thus, a complete unit providing high-performance distillation was supplied and commissioned out of one hand, integrated by a wide & complete portfolio of Pfaudler technologies, systems and services.

Pfaudler has demonstrated with this project, once more, its expertise in single-source supplying, starting from the design, through the construction to the commissioning of the equipment. For the customer, it means the reduction of the interfacing between suppliers and the security that all components of the system are designed and manufactured consistently for a fully integrated and operational system.

Contact Pfaudler today to learn more (Vincent.Petrilli@pfaudler.com)